In the fast-paced world of commercial kitchens, maintaining a clean and efficient operation is crucial. One often overlooked aspect is the proper installation of grease traps. These traps play a vital role in preventing grease and other waste materials from entering the sewer system, protecting both the environment and the health of individuals working in such establishments.

Understanding the Importance of Grease Trap Installation

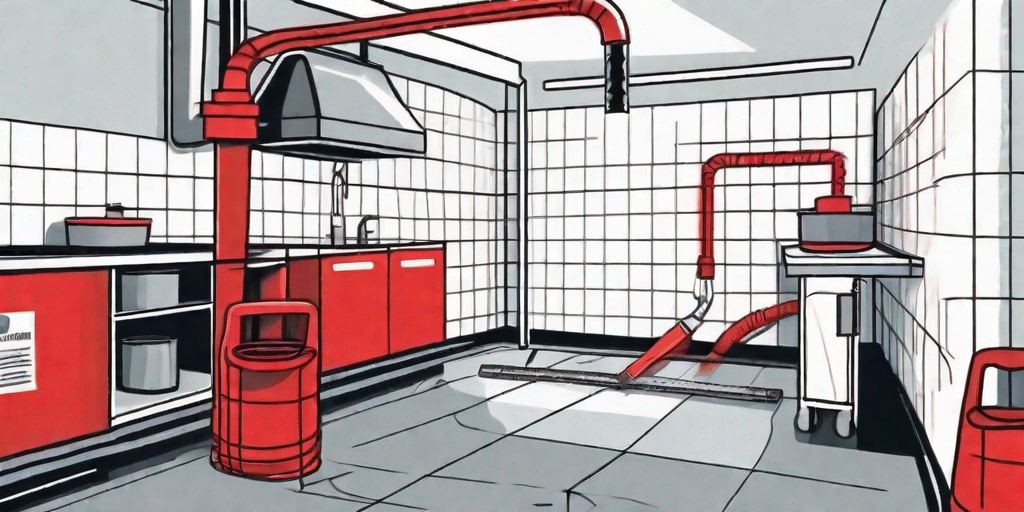

Grease traps act as a barrier, intercepting and trapping solid waste, fats, oils, and grease (commonly known as FOG) before they can cause disruptions in the plumbing system. Without proper grease trap installation, these substances can accumulate and clog drainage pipes, leading to costly repairs and potential violations of environmental regulations.

When it comes to maintaining a well-functioning plumbing system, grease trap installation is crucial. Not only does it prevent blockages and costly repairs, but it also plays a significant role in preserving the environment and ensuring the health and safety of kitchen staff and customers.

The Role of Grease Traps in Commercial Kitchens

In commercial kitchens, the volume of grease and waste produced on a daily basis is substantial. The constant cooking, frying, and food preparation activities generate a significant amount of FOG that needs to be properly managed. This is where grease traps come into play.

Grease traps provide an essential mechanism for capturing these substances, allowing for easier disposal and preventing them from contaminating the municipal sewer system. By separating FOG from wastewater, grease traps help minimize the risk of sewer blockages and backups, ensuring a more hygienic and efficient kitchen environment.

Imagine a bustling commercial kitchen, with chefs working tirelessly to prepare delicious meals for their customers. Without a properly installed grease trap, the plumbing system would quickly become overwhelmed with FOG, leading to a myriad of problems. Clogged pipes, foul odors, and unsanitary conditions would not only disrupt the kitchen’s operations but also put the health and safety of everyone involved at risk.

Environmental and Health Implications of Grease Traps

The disposal of grease and other FOG materials into the drainage system poses significant environmental and health risks. When these substances solidify in pipes, they cause blockages and impede the flow of wastewater. This can lead to overflows, releasing harmful materials into water bodies and compromising local ecosystems.

Imagine a scenario where a commercial kitchen neglects to install a grease trap. As time goes by, the FOG accumulates in the pipes, creating a thick layer that restricts the flow of wastewater. Eventually, the pressure builds up, causing a catastrophic sewer backup. The overflow of contaminated water not only damages the kitchen’s infrastructure but also pollutes nearby rivers or streams, endangering aquatic life and disrupting the delicate balance of the ecosystem.

Additionally, the accumulation of grease and FOG creates a breeding ground for bacteria, odors, and pest infestations, jeopardizing the well-being of kitchen staff and customers. The combination of heat, moisture, and organic matter provides an ideal environment for harmful bacteria to thrive. These bacteria can cause foodborne illnesses, putting the health of anyone consuming the kitchen’s food at risk.

By installing a grease trap, commercial kitchens can effectively mitigate these environmental and health risks. The trap acts as a preventive measure, intercepting FOG and preventing it from entering the drainage system. This not only ensures compliance with environmental regulations but also promotes a cleaner, safer, and more sustainable kitchen environment.

The Crowley Advantage in Grease Trap Installation

When it comes to professional grease trap installation, Crowley is the leading name in the industry. With decades of expertise and experience, they have garnered a reputation for excellence, reliability, and exceptional service.

Crowley’s Expertise and Experience

Crowley understands the unique requirements and challenges associated with commercial kitchens. Their team of highly skilled technicians possesses extensive knowledge in designing and installing grease trap systems tailored to specific needs. By staying up-to-date with the latest industry standards and regulations, Crowley ensures that their installations meet and exceed all compliance requirements.

Quality of Materials and Equipment Used by Crowley

In addition to their expertise, Crowley prioritizes the use of high-quality materials and cutting-edge equipment in their installations. This commitment to excellence guarantees the longevity and efficiency of the grease traps they install. By utilizing durable and reliable products, Crowley ensures that their clients can count on their grease trap system to perform optimally, even in demanding kitchen environments.

Steps in Crowley’s Grease Trap Installation Process

To provide their clients with the most efficient and reliable grease trap installations, Crowley follows a meticulous process that encompasses various stages.

Initial Consultation and Site Inspection

The first step in Crowley’s installation process involves performing an initial consultation and site inspection. During this phase, their team assesses the specific needs and challenges of the commercial kitchen. This allows them to understand the layout, plumbing requirements, and grease production of the establishment, ensuring an accurate and customized installation plan.

Design and Planning of Grease Trap System

Following the site inspection, Crowley’s team utilizes their expertise to design a grease trap system that maximizes efficiency and meets local regulations. Attention is given to factors such as the size and capacity of the grease trap, the location for optimal functionality, and the necessary connections to the plumbing system.

Installation and Testing of the Grease Trap

Once the design phase is completed, Crowley proceeds with the installation process. Their skilled technicians handle every aspect, from excavation and plumbing connections to the actual placement and securing of the grease trap. Throughout the installation, rigorous quality control measures are implemented to ensure everything is functioning correctly. Finally, thorough testing is performed to verify the trap’s effectiveness in capturing grease and other waste materials.

Maintaining Your Crowley Grease Trap

After the successful installation of a Crowley grease trap, proper maintenance is crucial to guarantee its long-term functionality and efficiency.

Routine Cleaning and Maintenance Tips

Regular cleaning and maintenance are essential to prevent the buildup of grease and debris inside the trap. Crowley recommends routine inspections and cleanings by professional technicians to ensure optimal performance. This involves removing accumulated solids, grease, and other waste materials, as well as inspecting and cleaning the inlet and outlet pipes.

Troubleshooting Common Grease Trap Issues

Despite regular maintenance, grease traps may occasionally encounter issues. Crowley’s experienced technicians are well-equipped to diagnose and resolve any common problems that may arise. From identifying clogs and blockages to addressing odors or other performance concerns, their team is readily available to provide prompt and effective solutions.

Choosing Crowley for Your Grease Trap Needs

When it comes to grease trap installations, choosing an industry leader like Crowley offers numerous advantages and benefits.

Customer Satisfaction and Service Excellence

Crowley’s commitment to customer satisfaction is unrivaled. They prioritize clear communication, working closely with clients to address their specific requirements and concerns. Throughout the entire installation process, Crowley maintains a high level of professionalism, ensuring that every customer receives a solution that exceeds their expectations.

Competitive Pricing and Value for Money

In addition to their outstanding service, Crowley offers competitive pricing without compromising on quality. They understand the importance of cost-effectiveness for businesses, ensuring that their grease trap installations deliver long-term value for money. By combining affordable pricing with their industry expertise, Crowley provides an unmatched level of service and satisfaction.

In conclusion, the proper installation of grease traps in commercial kitchens is essential to maintain a clean and efficient operation while protecting the environment and the health of individuals. Crowley stands out as the industry leader in grease trap installation, offering expertise, high-quality materials, and a meticulous process to ensure optimal performance. By choosing Crowley, businesses can trust that their grease trap installations will be reliable, efficient, and compliant with all regulatory requirements. With their commitment to customer satisfaction and competitive pricing, Crowley is the top choice for all grease trap needs.